Production of Milanaise Bracelets

Milanaise - A braid

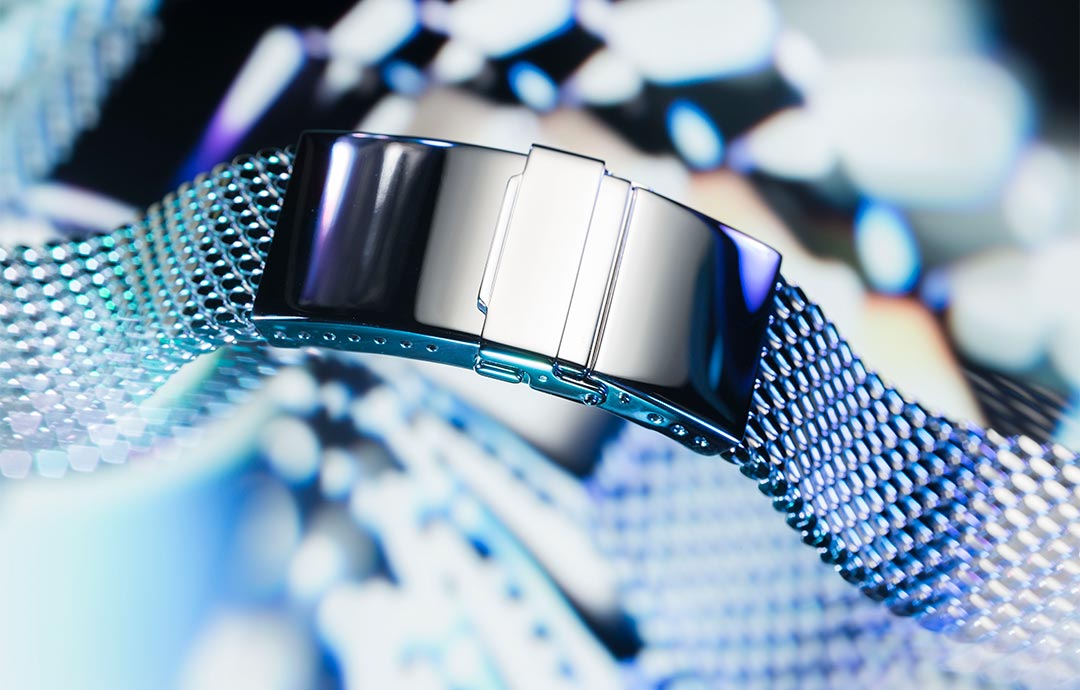

Milanais tapes with their cuddly and fine mesh are a very special design element to make a wristwatch look elegant and sporty at the same time. Their name is due to their origin: Milan (Italian Milano). The raw materials are wires in the respective metal alloy (316L stainless steel, gold, platinum or titanium) and in different thicknesses (from 0.28 to two millimeters). The bracelets are then braided from the fine wires.

The production

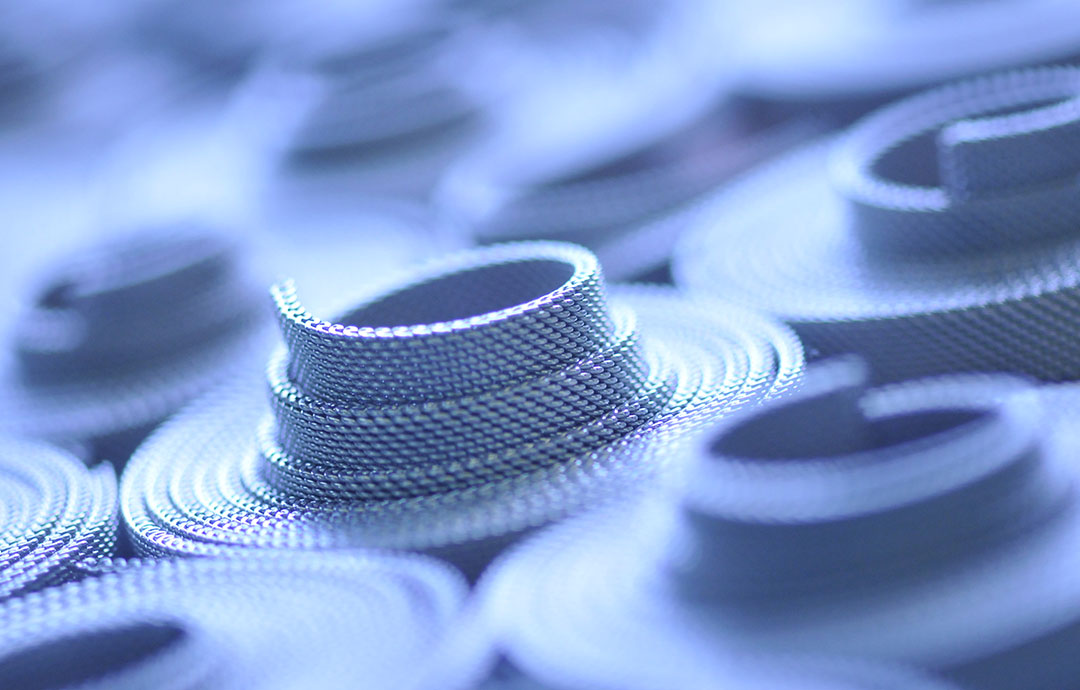

The wires are delivered on spools. These coils are placed on a Milanaise machine. As with a sewing machine, the wire runs into the machine, which then turns it into a uniform spiral and cuts it off at a certain length. The process is repeated automatically so that one sprite is wound one after another in the other until a carpet of a multiplicity of spirals twisted into one another is created.

The carpet

The resulting carpet is then cut into strips on a cutting table. Since the cut must always be made in the same notch, this process is done by hand.

The individual pieces are strung together by the two ends of the individual spirals are rotated together. Subsequently, the sharp edges of the strip resulting from the cutting process are deburred by hand on a grinding wheel (ground).

The Milanaise network

So that the mesh can not dissolve, it is flattened and compacted. Since every deformation process causes a stiffening of the material, the mesh passes through an annealing furnace to balance the tension. After the annealing process, the strip comes in a vibrating machine. Here, the band is guided over multiply arranged hard rubber rollers and thus made movable.